ABOUT

US

Kunming Technology Kaiji Cisco Technology Co., Ltd.

The company has a long-term engaged in mining science and technology research professional team, and Kunming University of Science and Technology has established a close cooperative relationship. The "Mineral Green Separation Equipment and Technology Research Center" established in cooperation is specialized in the research of secondary technology of tailings utilization, clean utilization technology of fine-grained minerals, fine-grained gravity separation technology, and green recovery of fine-grained mineral resources. The scientific research team led by chief expert Yang Bo, after more than 10 years of scientific and technological research, has achieved remarkable recovery effect on fine-grained minerals.

R & D Experience

Cooperation Unit

Customer Service

patented technology

Products

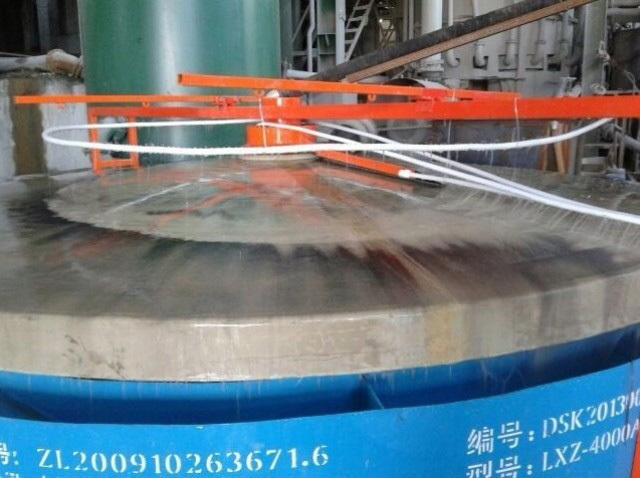

The new technology of "KGS suspension vibration" greatly improves the recovery efficiency of fine-grained minerals and expands the application space of this clean recycling technology.

NEWS INFORMATION

COOPERATION

Looking forward to cooperating with you

Beijing Mining and Metallurgical Research Institute, Changsha Nonferrous Metals Research Institute, Changsha Mining and Metallurgical Research Institute, Zhengzhou Institute of Comprehensive Utilization of Minerals of the Ministry of Land and Resources and other 22 well-known domestic scientific research institutes listed it as a key to promote new mineral processing equipment. The business covers suspended vibration concentrator, mineral processing equipment, suspended vibration beneficiation equipment, new gravity separation equipment, fine grain gravity separation technology, fine grain mineral clean utilization technology, tailings utilization secondary technology. At present, it has been applied in more than 100 well-known domestic enterprises in Yunnan, Hunan, Jiangxi, Guangxi, Henan, Inner Mongolia, Liaoning and other provinces, and exported to Bolivia, Southeast Asia and other countries and regions.

Contact UsNEWS INFORMATION

Unveiling Innovations: Kunming Technology Kaiji Cisco Technology Co. in the Spotlight

Dive into the latest news and insights from Kunming Technology Kaiji Cisco Technology Co., a leader in innovation.

2025-10-06

Unveiling the Innovations of Kunming Technology Kaiji Cisco Technology Co.

Discover the latest developments and news from Kunming Technology Kaiji Cisco Technology Co. and its impact on the tech landscape.

2025-10-06

Unlocking the Secrets of Beneficiation in Today's News Landscape

Explore the latest trends and insights on Beneficiation and its impact on various sectors in this engaging article.

2025-10-05

Unlocking the Secrets of Beneficiation: What You Need to Know

Dive into the world of beneficiation, its processes, and its impact on various industries.

2025-10-05