Wenshan Funing Gold Mine discarded 0.4g/ton, and other tailings that cannot be selected by other equipment. Rough selection and selection by suspension vibration concentrator were used to obtain a good index of 15g/ton of gold grade and a recovery rate of 40%, which increased the annual output value of the mine by more than 1000 million yuan and achieved remarkable economic benefits.

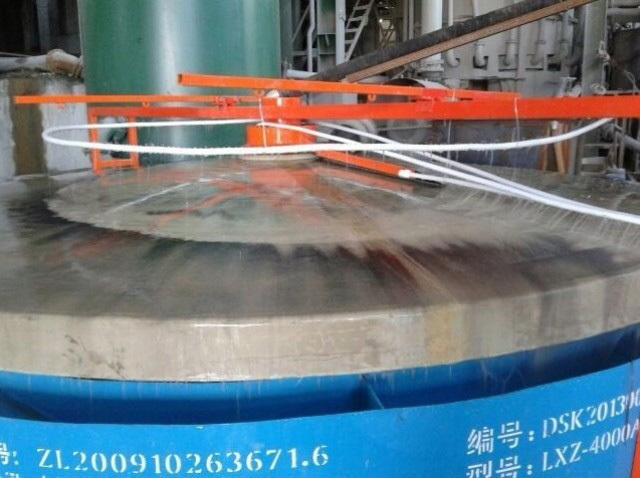

Jiangxi Shangyou Yingqian Mining Concentrator

The flotation of scheelite tailings from Jiangxi Shangyou Yingqian Mining Concentrator has an ore volume of 30 tons/day, a tailings concentration of 10%, a scheelite grade of 0.5~1.2, and -200-purpose fine-grained minerals account for 90%.

After the production tailings are concentrated, the concentrate containing 20.13% scheelite can be obtained by a suspension vibration cone concentrator, and about 500kg of concentrate can be produced every day, with remarkable economic benefits.

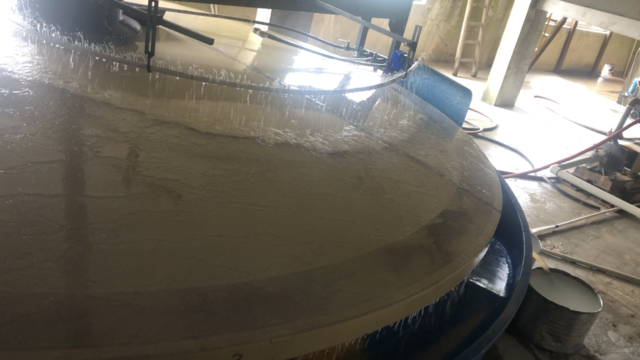

Jiang Tungsten Group Mine Concentrator

Tieshanlong Tungsten Ore Concentrator under Jiang Tungsten Group uses a suspended vibration cone concentrator to recover fine tungsten ore from its tailings. After screening, it produces about 100t of fine tungsten sludge every day, with -200 mesh accounting for 100 and grade 0.3. The equipment has been operated for half a year and the investment cost has been recovered.

Through a variety of investigation and comparison, based on the suspension vibration ore machine selection to obtain good technical and economic indicators, in 2018, Jiang Tungsten Group specifically issued relevant regulations, its mine plant fine-grained mud treatment are using suspension vibration ore machine as the primary technical means.

Hunan Polymetallic Mineral Concentrator

Hunan Polymetallic Mine Concentrator has a slurry volume of 100 tons/day, a concentration of 24%, a tungsten grade of 1-2%, a tin grade of 0.3, and a fine particle ore of -400 mesh accounting for about 90%. The mixed concentrate with a tungsten grade of 25% and a tin grade of more than 6% can be obtained by adopting the beneficiation process composed of 26 suspended vibration cone concentrators. The tungsten recovery rate is 45% and the tin recovery rate is 40%, annual output of tungsten trioxide 202 tons, 36 tons of tin metal, annual output value of up to more than 2200 million yuan.

Yunnan Lancang Lead and Zinc Xingrui Trading Co., Ltd.

The flotation tailings of Lancang lead-zinc mine have an ore volume of 200 tons/day, tailings concentration of 28%, sulfur content of 15%, and fine particles of -200 purpose account for 70%.

Sulfur concentrate with a sulfur grade of 42.30% can be obtained by using 6 suspended vibration cone concentrators for one separation, with a recovery rate of 50.09%. It can produce 10000 tons of sulfur powder every year, with an output value of more than 280 million yuan.

Shougang ferroboron uranium ore separation

The suspended vibration cone concentrator can also be applied to the recovery of manganese, chromium, titanium, antimony, uranium, tantalum, niobium, lead, zinc, gold, sulfur, barite and other minerals, such as Panzhihua Iron and Steel Mining, Yunnan Lancang Lead-Zinc Concentrator, Guangxi Limu Antimony Ore, Shougang Boron Iron Concentrator, Hebei Chengde Gold Concentrator, Jinhui Environmental Protection Technology Co., Ltd., etc.

Yichun Tantalum Niobium Ore Selection

The suspended vibration cone concentrator can also be applied to the recovery of manganese, chromium, titanium, antimony, uranium, tantalum, niobium, lead, zinc, gold, sulfur, barite and other minerals, such as Panzhihua Iron and Steel Mining, Yunnan Lancang Lead-Zinc Concentrator, Guangxi Limu Antimony Ore, Shougang Boron Iron Concentrator, Hebei Chengde Gold Concentrator, Jinhui Environmental Protection Technology Co., Ltd., etc.

The suspended vibration cone surface concentrator is used in Yunnan Yuxi COSCO Mining, COSCO Iron Mine site, Kungang Roots Iron Mine, Dongchuan iron ore and other enterprises to recover fine hematite and mirror iron ore, and has obtained significant economic benefits.