Introduction of suspended vibration cone concentrator

Research and development and production of precious metal compounds, precious metal heterogeneous and homogeneous catalysts, precious metal electronic slurry, precious metal catalytic sensors and precious metal electroplating products; Purification and processing services for precious metal wastes containing gold, platinum, rhodium, palladium, iridium, ruthenium, silver, etc. Trade in precious metal raw materials such as platinum, rhodium, palladium, iridium, ruthenium and silver; Research, development and practice of precious metal recovery technology.

Classification

Key words:

containing gold

purple red crystal

Silver

Product Introduction

I. Suspension Vibration Cone Concentrator (ZL 200910263671.6)

Separation principle of 1.1 suspended vibration cone concentrator

The suspended vibration cone concentrator is a new type of fine grain gravity separation equipment developed on the basis of the Baigno shear loose theory and the principle of flow membrane beneficiation.

When the uniformly stirred ore slurry enters the roughing area of the sorting surface from the ore feeder after being replenished by the ore slurry replenishment pipe, the ore slurry flow spreads out into a fan shape and flows to the surrounding area, and the flow film gradually decreases from thickness to thickness in the flow process. Under the action of its own gravity and the shear repulsion generated by the rotary vibration, the mineral particles are moderately loose and stratified on the sorting surface, and the rotation of the sorting surface, as well as the sorting action of the involute washing water and the concentrate washing water, bring the minerals of different densities into the tailings tank, the medium ore tank and the concentrate tank in turn.

1.2 equipment structure

The suspended vibration cone concentrator is composed of 6 parts: main machine, sorting surface, ore feeding device, water feeding device, ore receiving device and electric control system. The equipment structure is shown in Figure 1.

Figure 1 Equipment structure

Fig 1 Structure of device

Scope of application of 1.3 suspended vibration cone concentrator

"Suspension vibration cone concentrator" can be widely used in tungsten, tin, lead, zinc, titanium, antimony and other non-ferrous metals, iron, manganese, chromium and other ferrous metals, uranium, tantalum, niobium, gold and other rare and precious metals, barite, sulfur and other non-metallic ore beneficiation, as well as a variety of new and old tailings in the recovery of useful minerals.

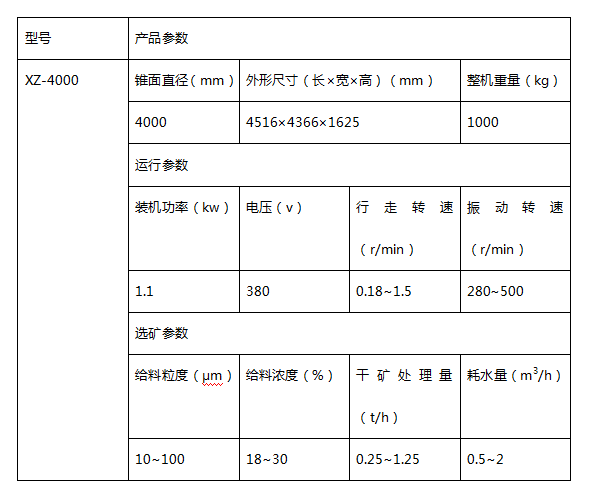

1.4 technical parameters

1.5 product advantages

As a highly targeted product, "suspended vibration cone concentrator" is unique, unique and reliable in the world. has the following advantages:

1, environmental protection: gravity beneficiation equipment, no need to add any chemicals, so it will not cause pollution to the environment;

Low energy consumption: using inverter control, the operating power is only about 0.7kw;

3. Large processing capacity: the processing capacity is more than 10 times that of the traditional slime shaker;

4. The materials with grain size width of -100 μm(150 mesh) can be selected without grading, and the index is stable;

5, less infrastructure investment: equipment vibration is small, infrastructure requirements are not high, installation and operation is simple;

6. Wide application space: It can be used for the separation of fine-grained minerals with different proportions, and the application space is broad.